Solution

Solving user problems and core technological innovation are the key development strategies of the company. Changsha Zoomlian Pump Co., Ltd. has a new product R&D center and a CAD/CAE design system, with independent development, design, and research capabilities for water pumps. For many years, it has maintained a development path that combines traditional and new products, and vigorously promotes the brand strategy.

Self-Balanced Multistage Pump Structural Diagram

08

2025-09

Wear-resistant multistage pump for coal mines

05

2025-09

Horizontal Multi-stage Booster Pump

05

2025-09

Corrosion- and Wear-Resistant Centrifugal Pump

05

2025-09

High-Temperature, High-Pressure Pump

05

2025-09

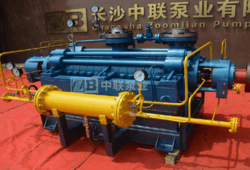

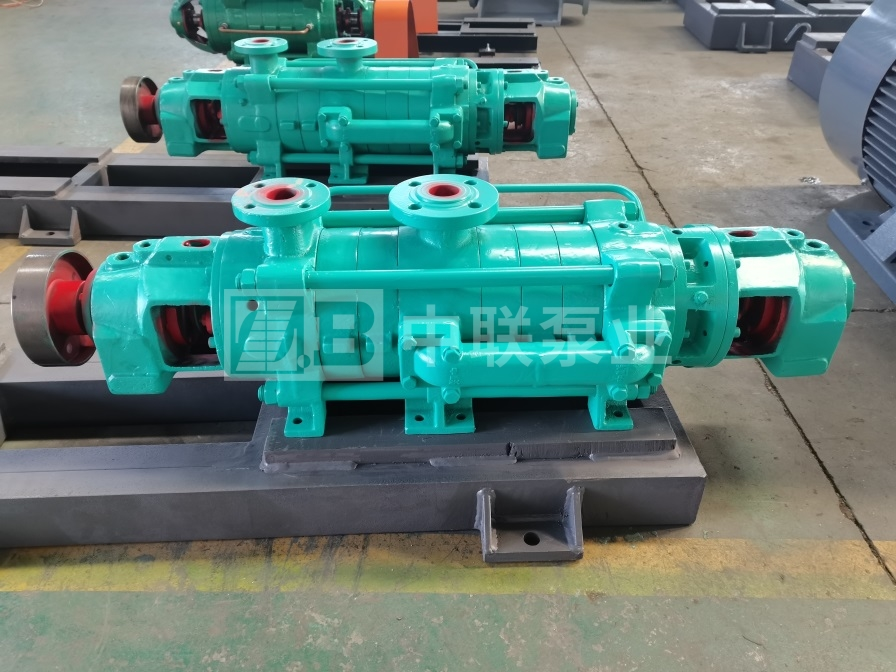

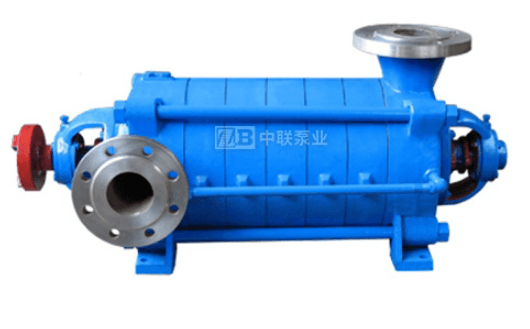

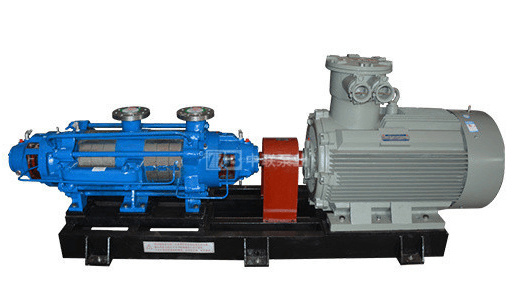

Type D Horizontal Multistage Centrifugal Pump

05

2025-09

05

2025-09

05

2025-09

05

2025-09

Desulfurization Slurry Circulation Pump

05

2025-09

MDEA Natural Gas Decarbonization Pump

05

2025-09

Highly Corrosion-Resistant Pump

05

2025-09

05

2025-09

QW-Type Submersible Sewage Pump

05

2025-09

High-pressure centrifugal water pump

05

2025-09

05

2025-09

05

2025-09

05

2025-09

Type D Multistage Clear Water Pump

05

2025-09