The desulfurization slurry circulation pump is one of the most critical pieces of equipment in a thermal power plant's flue gas desulfurization system. Its primary function is to continuously circulate the slurry within the absorption tower, ensuring a steady supply of lime浆 that is sprayed downward from the top of the tower. This process facilitates countercurrent contact between the slurry and harmful gases such as SO₂ (sulfur dioxide), nitrogen oxides, and carbon monoxide inside the tower, effectively absorbing these corrosive gases and protecting the corrosion-resistant materials lining the absorption tower from damage caused by high-temperature flue gas. More than half of the electricity consumed by the FGD flue gas desulfurization system is used to power the absorption tower circulation pumps, making reliability and longevity of these pumps paramount. As a result, the pumps must operate with exceptional efficiency. The hydraulic design, structural configuration, and selection of flow-path components for the FGD slurry circulation pump directly influence the pump's operational efficiency and overall reliability.

Factors for Selecting Circulating Pumps for Flue Gas Desulfurization Slurry in Power Plants

The lime slurry circulated by the desulfurization pump contains a large number of fine, highly abrasive solid particles. The liquid is slightly acidic, with a pH ranging from 4 to 6, and its temperature stays between 45°C and 60°C. Additionally, it includes high concentrations of chloride ions (Cl⁻) and sulfate ions, making it essential to use corrosion- and wear-resistant materials to effectively address the challenging issue of friction-induced corrosion.

During prolonged continuous operation, the impeller surface of the slurry circulation pump is subjected to destructive forces such as impact erosion, corrosion, and cavitation caused by the lime slurry. Over time, the blades gradually wear thin, developing pitting cavities, and in severe cases, even leading to chipping, notches, cracks, and perforations. These damages can accumulate over time, ultimately resulting in structural failure and rendering the impeller unusable. At the same time, such degradation significantly reduces the pump's operational efficiency and increases energy consumption. Therefore, there is an urgent need for a reliable method to repair pump components—specifically impellers—aimed at lowering procurement costs, minimizing spare parts inventory, and ensuring that component lifespans exceed those of new parts. Moreover, this approach should further extend the service life of impellers while reducing the labor intensity associated with frequent disassembly and reassembly by workers.

Currently, desulfurization slurry circulation pumps are broadly categorized into three types based on material: metal pumps, cast iron-lined rubber pumps, and ceramic pumps. Among these, metal pumps are now widely adopted by most power plants in China, typically made from duplex stainless steel or high-chromium cast iron. Pumps manufactured from these materials exhibit superior wear and corrosion resistance, making them ideal for desulfurization applications.

Power plant flue gas desulfurization slurry circulation pump model

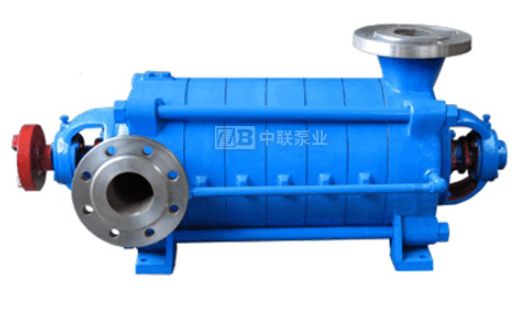

The DF-type stainless steel desulfurization slurry circulation pump is a horizontal, single-suction, multistage, segmental corrosion-resistant chemical pump designed to handle liquids with temperatures ranging from -20°C to 105°C—provided these liquids are free of solid particles and exhibit corrosive properties. The pump’s inlet can withstand pressures up to 0.6 MPa. All flow-path components of the DF-type highly corrosion-resistant pump are made of stainless steel, while the shaft is also crafted from stainless steel. In terms of sealing mechanisms, the pump offers both packing seals and mechanical seals. Packing seals are typically used in applications where leakage tolerance is relatively high or when the medium contains solid particles. On the other hand, mechanical seals are ideal for scenarios involving high temperatures, high pressures, or corrosive environments, where stringent leakage control is essential. Both types of seals serve to effectively seal the pump at its two ends, preventing the internal medium from leaking out and ensuring the overall integrity and performance of the pump. With the exception of the DF155-30 and DFHG models, which feature horizontal suction and vertical discharge, all other DF-type pump models are designed with vertical suction and vertical discharge configurations.

↑Click the image to learn about the DF-type stainless steel desulfurization slurry circulation pump Product details and Price Information ↑

The DF-type desulfurization slurry circulation pump features precision-cast flow components throughout, ensuring precise flow passage dimensions and exceptional surface smoothness. Compared to conventional multistage pumps available on the market, it delivers an average efficiency improvement of over 2% in real-world tests, offering outstanding energy-saving performance. Additionally, an O-ring seal is installed at the mating surfaces between the balance ring and the pump housing, effectively preventing high-pressure water from entering the balance chamber—thus safeguarding the balance disc's effectiveness and minimizing wear on the disc, ultimately extending the product's service life. Depending on specific user requirements, the balance disc and balance ring can be made from materials such as hard alloy overlay welding, alloy steel, or QT60O-Mn2 ductile cast iron with alloy additives, all boasting high surface hardness and excellent wear resistance for enhanced durability and longevity.

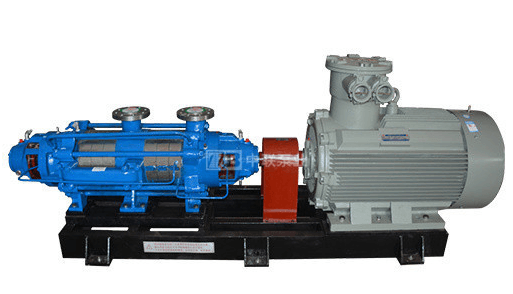

The DFP-type self-balancing flue gas desulfurization slurry circulation pump is a single-suction, multistage, sectional corrosion-resistant centrifugal pump. Developed with an advanced impeller hydraulic model or a unique dual-stage impeller design, it represents a new generation of highly efficient, energy-saving chemical centrifugal pumps equipped with an innovative balance-free mechanism. Constructed from cast stainless steel, this pump is designed to handle corrosive liquids free of solid particles and at temperatures below 80°C. The pump’s inlet can withstand pressures up to less than 0.6 MPa. Featuring mechanical sealing technology combined with a dual-sealing system—employing a labyrinth seal at the front end and a magnetic seal at the rear—the pump boasts a robust and secure sealing design, ensuring reliable mechanical integrity. As a result, the rotor components experience no axial movement during pump startup or shutdown, and there are no axial pulsations during operation. This design effectively addresses the longstanding challenges plaguing nitric acid pumps, such as poor mechanical seal reliability and frequent leakage issues. Equipped with a self-balancing mechanism and crafted entirely from corrosion-resistant stainless steel, the pump not only delivers exceptional durability and sealing performance but also achieves superior energy efficiency. It stands as an excellent next-generation replacement for traditional multistage centrifugal pumps that rely on balance disc mechanisms.

↑Click the image to learn about horizontal stainless steel multistage centrifugal pumps Product details and Price Information ↑

The design of the DFP-type self-balancing flue gas desulfurization slurry circulation pump is fundamentally based on practical safety, cost-effectiveness, reliable fault-free operation, and low maintenance costs throughout the entire pump unit's operational lifecycle. The pump's key design features are briefly outlined as follows:

● Advanced modular design with a combination of components, making extensive use of time-tested, locally sourced parts that boast high interchangeability.

● High-strength, high-quality materials and a variety of options for inlet, outlet flanges, and nozzle designs enhance the pump's ability to handle significant nozzle loads. The robust, high-quality pump casing features a tightly structured design, ensuring a service life up to 5 times longer than that of conventional castings. Additionally, the impeller and diffuser—key components in the flow path—are manufactured using precision casting, resulting in surfaces that are exceptionally smooth and uniform. This not only boosts efficiency by more than 2% compared to standard castings but also allows the pump to readily meet users' specific system requirements under unique operational conditions.

● A quick assembly and disassembly design allows the pump to replace seals and bearing components without removing the pump body or the inlet and outlet pipelines, ensuring efficient inspection and maintenance time.

● A combination of high efficiency, high reliability, and low cost. Thanks to the excellent coordination between the impeller and guide vanes, along with optimized clearance gaps and a generously designed axial throttling mechanism, the pump maintains exceptional stability and remarkably high operational efficiency even after prolonged use.

● Excellent cavitation performance is achieved through the use of an advanced impeller hydraulic model or a special double-suction impeller design, eliminating the need for users to separately install a booster pump or increase the height of the suction tank.

● The pump features a symmetrical arrangement, which effectively eliminates axial forces. Any remaining axial force is borne by a pair of back-to-back angular contact ball bearings. The rotor assembly, with its symmetrically arranged impellers, ensures that the high- and low-pressure zones at either end of the impeller counterbalance each other, maintaining axial force equilibrium. Meanwhile, transient axial forces during variable operating conditions—and residual axial forces arising from manufacturing tolerances and spiral seals—are handled by the thrust-bearing mechanism within the bearing assembly. This design eliminates the need for conventional axial-force balancing components such as balance discs or balance drums, completely preventing rotor seizure, component damage, shaft breakage, or even motor burnout caused by the failure of these mechanisms during sudden changes in pump operation. As a result, the pump’s service life is significantly extended.

● Safe pump body sealing design. Depending on the specific pressure and structure, the pump body features either a metal-to-metal hard seal or an O-ring seal.

● An intermediate tap and a minimum flow system can be added according to user requirements.

● The unique structural strength design enables the pump to achieve a single-stage head of up to 15 MPa (150 m) and an outlet pressure of up to 15 MPa (total head equivalent to 1500 m). Additionally, the core assembly—comprising the bearing and rotor—is completely unaffected by temperature fluctuations, showcasing excellent resistance to thermal shock.

● When using mechanical seals without axial movement, the issue of failure in the dynamic and static ring friction surfaces due to poor contact—commonly seen in older multi-stage pumps with axial play—is completely eliminated. In actual operation, this design ensures zero leakage, not a single drop escapes.

Previous:

Recommended Information

Related Products