The D pump is a horizontal, single-suction, multistage, sectional centrifugal pump characterized by high efficiency, a wide performance range, safe and stable operation, low noise levels, long service life, and convenient installation and maintenance. The D-type pump delivers flows ranging from 3.7 to 1,350 m³/h and can achieve heads of 49 to 1,800 m, making it suitable for conveying clean water or other liquids with physical and chemical properties similar to water. Additionally, by modifying the material of the pump’s wetted components, adjusting the sealing configuration, or adding a cooling system, the D pump can also handle hot water, oils, corrosive fluids, or media containing abrasive particles. The product complies with the JB/T 1051-93 standard titled "Types and Basic Parameters of Multistage Clean Water Centrifugal Pumps."

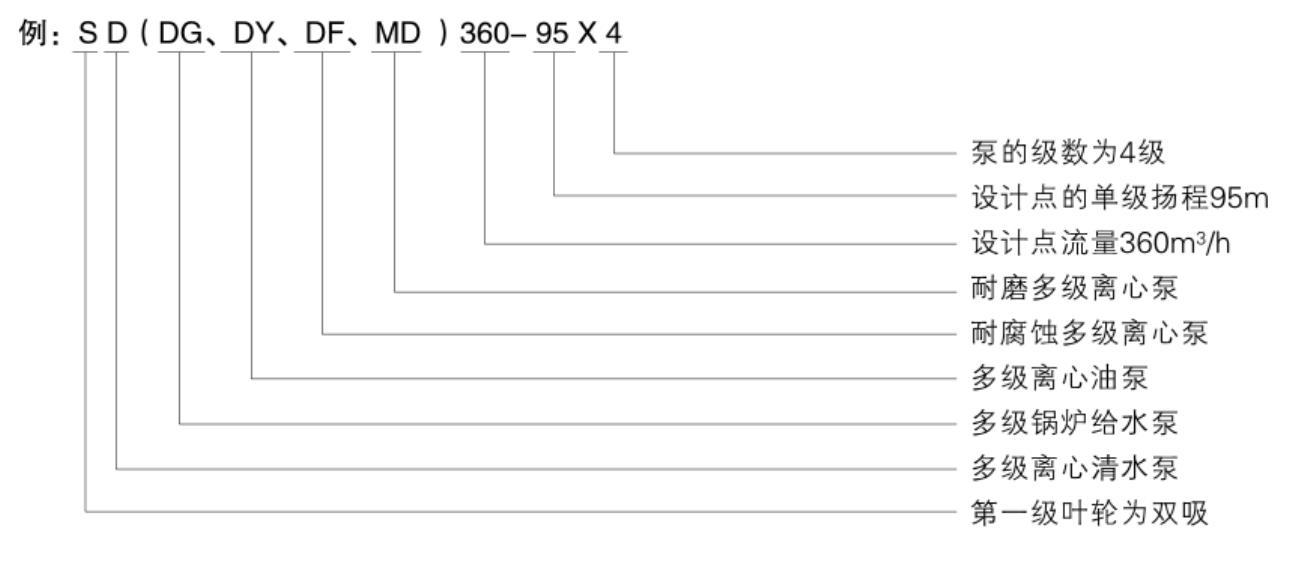

D-type horizontal multistage centrifugal pump model:

Type D clear water multistage centrifugal pump: Designed for conveying clean water or liquids with physicochemical properties similar to clean water—provided they are free of solid particles and have temperatures below 80°C. Primarily used in industrial and municipal water supply and drainage systems, boosting water pressure in high-rise buildings, supporting garden irrigation, fire protection boosting, long-distance water delivery, heating and cooling systems, bathroom applications for circulating and pressurizing hot and cold water, and as auxiliary equipment for various installations. Particularly well-suited for supplying feedwater to small-scale boilers.

↑Click the image to learn about the D-type multistage centrifugal clear water pump Product details and Price Information ↑

DF-Type Corrosion-Resistant Multistage Centrifugal Pump This is a single-suction, multistage, sectional-type corrosion-resistant centrifugal pump designed for conveying corrosive liquids that are free of solid particles and have temperatures ranging from -20°C to 105°C. The pump's inlet is rated to handle pressures below 0.6 MPa. Users can select the appropriate pump material, sealing configuration, pump design, and determine the motor capacity based on factors such as the name, concentration, specific gravity, operating temperature, and inlet pressure of the liquid being transported.

↑Click the image to learn about the DF-type corrosion-resistant multistage centrifugal pump Product details and Price Information ↑

The DG-type boiler feedwater multistage centrifugal pump is a horizontal, multistage, single-suction sectional centrifugal pump designed for conveying clean water at temperatures below 280°C, or non-corrosive liquids with physical and chemical properties similar to water. It is widely used in industries such as power plants, metallurgy, and heating systems for boiler feedwater applications, with extremely high head capabilities reaching up to 1,800 meters.

↑Click the image to learn about the DG-type boiler feedwater multistage centrifugal pump Product details and Price Information ↑

The MD-type mining centrifugal pump is a horizontal, single-suction, multistage centrifugal pump. Built upon the D-type pump, it features components in the flow path made from wear-resistant materials, offering advantages such as superior abrasion resistance and extended service life. This pump is particularly well-suited for mine drainage applications, capable of handling mine water containing solid particles no larger than 1.5%, as well as other liquids with temperatures not exceeding 80°C. It finds widespread use in steel plants, mining operations for drainage purposes, sewage transportation, and similar industrial settings. The "MD" designation indicates that this equipment is specifically designed for use in coal mines and thus requires both a "Coal Safety Certificate" and a "Mine Safety Certificate."

↑Click the image to learn about the MD type Mining multi-stage centrifugal pump Product details and Price Information ↑

DY-type horizontal multistage centrifugal oil pump: Designed for conveying petroleum and petroleum products with a viscosity of less than 120 cSt, free from solid particles. The medium temperature ranges from –20°C to 150°C, and the allowable inlet pressure is up to 0.6 MPa.

↑Click the image to learn more DY-Type Multistage Centrifugal Oil Pump Product details and Price Information ↑

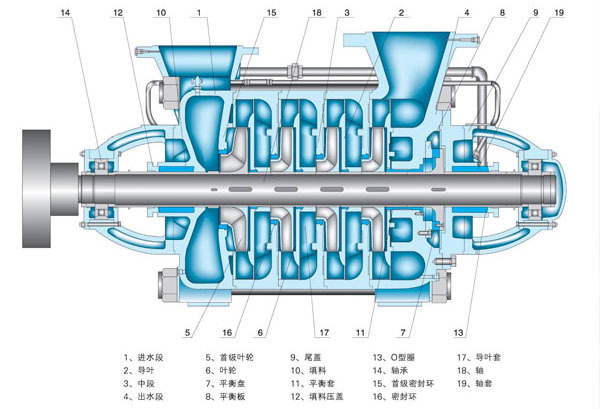

D-type centrifugal pump structural features:

D., DG, DF, DY, and MD-type centrifugal pumps can have their suction inlets oriented horizontally or vertically upward. The pump's casing components—such as the inlet section, middle section, and outlet section—are securely connected as a single unit via tension bolts. Both ends are equipped with bearing assemblies, and the number of pump stages is selected based on the desired head.

The rotor section of this pump series primarily consists of a shaft along with components mounted on the shaft, such as impellers, shaft sleeves, and balance discs—among which the number of impellers depends on the pump's stage configuration. The components on the shaft are securely fastened to it using flat keys and shaft nuts, ensuring they rotate as a single unit with the shaft. The entire rotor is supported at both ends by either rolling or sliding bearings. The specific type of bearing used varies depending on the model; however, none of these bearings are designed to handle axial forces, as these are counterbalanced by the integrated balance disc. Additionally, a balance-disc wear indicator is installed at the pump end to continuously monitor the condition of the balance disc and detect any signs of wear.

The sealing surfaces between the pump's suction section, middle section, and discharge section are all sealed using sealant or "O"-rings. Additionally, the rotor assembly is sealed against the stationary components by means of sealing rings, guide vane sleeves, and other such elements. When wear on the sealing rings and guide vane sleeves begins to affect the pump's performance, they should be replaced promptly.

There are two types of shaft sealing methods: mechanical seals and packing seals. When a pump uses a packing seal, the packing rings must be positioned correctly, and the tightness of the packing should be just right—allowing only a steady drip of liquid to seep out. All of the pump's sealing components are housed within a sealed cavity, which is continuously supplied with water at a specific pressure, serving functions such as water sealing, water cooling, or water lubrication. Additionally, a replaceable shaft sleeve is installed at the shaft seal area to protect the pump shaft.

The pump allows the rotor to move axially within the pump casing during operation. This type of pump typically uses rolling bearings with a dry-oil lubrication system. (Pumps of models D/DG8567 and D/DG155-67 can also be equipped with sliding bearings and dilute-oil lubrication systems, or alternatively, they may use rolling bearings with dry-oil lubrication.)

This series of pumps is directly driven by the prime mover via an elastic coupling. When viewed from the direction of the prime mover, the pump rotates clockwise.

The motors are typically configured as Y3 series motors, while YB3 series explosion-proof motors are used in environments with combustible and explosive gases.

If users have specific requirements for the pump’s materials and structure, they can discuss solutions with our company. We can adjust the inlet and outlet directions of the water pump according to user needs, and also accommodate multi-outlet designs and functionalities for this series of pumps.

Previous:

Next:

Recommended Information

Related Products