Type D Multistage Clear Water Pump This is a multi-stage, sectional centrifugal clear water pump, suitable for use in mining, industrial plants, and urban water supply and drainage systems. It is designed to convey clean water free of solid particles, abrasives, or suspended solids—specifically, liquids with physical and chemical properties similar to pure water. The temperature of the liquid being pumped can range from -20°C to 80°C, with an allowable inlet pressure of up to 0.6 MPa. Typically, the pump body is made of cast iron, as it handles chemically stable clear water that exhibits minimal corrosiveness. However, for vertical multi-stage clear water pumps, some models are also manufactured using stamped stainless steel. Material customization is available based on customer requirements. From a cost-performance perspective, horizontal clear water pumps commonly feature cast-iron construction.

Application scope of D-type multistage clear water pumps:

Suitable for industrial and municipal water supply and drainage, pressurized water supply in high-rise buildings, landscape irrigation, fire-fighting boosting, long-distance water delivery, heating systems, as well as cold and hot water circulation boosting and equipment integration in bathrooms—particularly ideal for feedwater supply to small boilers.

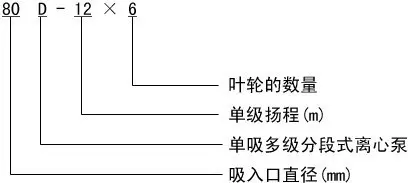

D-Type Multistage Clear Water Pump Model Description:

Example: 80D12X5

80—Pump suction inlet diameter (mm)

D—Multi-stage, Segmental Centrifugal Clear Water Pump

12—Pump head (m)

5—The pump has 5 stages.

D-Type Multistage Clear Water Pump Structural Description:

1. The hydraulic model is advanced, highly efficient, and offers a wide performance range.

2. The pump operates smoothly with low noise.

3. The shaft seal employs either a soft packing seal or a mechanical seal, ensuring safe and reliable sealing with a simple design that allows for quick and convenient maintenance.

4. The shaft features a fully sealed design, ensuring it remains free from contact with the medium, preventing corrosion and guaranteeing a long service life.

D-Type Multistage Clear Water Pump Structural Description:

1. Pump Casing Section: The pump casing section is primarily assembled into a single unit by bolting together components such as the bearing, front section, middle section, rear section, and guide vanes. The centerline of the suction inlet in the front section runs horizontally, while the centerline of the discharge outlet in the rear section is perpendicular to the horizontal plane.

2. Rotor Assembly: The rotor assembly primarily consists of bearings and components mounted on the shaft, including the impeller, shaft sleeve, balance disc, and other parts. The components on the shaft are securely fastened to it using flat keys and shaft sleeve nuts, ensuring they rotate as a single unit with the shaft. The entire rotor is supported at both ends by bearings housed within the pump casing. The number of impellers in the rotor assembly is determined based on the pump’s stage configuration.

3. Bearing Section: The D-type multistage centrifugal clear water pump features two types of bearings—sliding bearings and rolling bearings—depending on the specific model. Neither type is designed to withstand axial forces. During operation, the rotor should be allowed to move axially within the pump casing; therefore, radial bearings cannot be used.

4. Pump Sealing: The sealing surfaces between the pump’s front, middle, and rear sections are all sealed with molybdenum disulfide grease. The rotor section is sealed against the stationary parts using sealing rings, guide vane sleeves, and packing seals. When wear on the sealing rings or guide vane sleeves begins to affect the pump’s operation and performance, they should be replaced promptly.

5. Balance Mechanism: The balance mechanism consists of components such as the balance ring, balance disc, and balance sleeve. It is designed to counterbalance the axial force acting on the pump.

Previous:

Recommended Information

Related Products