The high-pressure ash water pump is auxiliary equipment for the washing and slag-handling processes in the pressurized coal-water slurry gasification unit. It is used to convey media—coal-ash-containing water—from the ash water treatment section. Specifically, a portion of the low-pressure ash water, after being recovered via steam stripping from the deaerator tank, is sent back into the gasification scrubbing tower for recirculation, while the remaining part serves as emergency quench water, anti-flushing water for the slag-lock valve, and pressurizing water for the lock hopper—all of which are fed directly into the gasification section. This process enables the efficient recycling of ash water. (In the coal-water slurry gasification process, the scrubbing tower ash water pump pressurizes the ash water, which is then delivered to the gas scrubbing tower. The ash water subsequently flows into a sedimentation tank, where it’s pumped by the ash water pump to the deaerator. From there, the ash water passes through a filter screen before being routed back into the ash water circulation pump, completing one full ash water cycle.)

The medium conveyed by the high-pressure ash water pump contains highly abrasive, hard particles—specifically, suspended particles with high hardness (calcium ion concentration as high as 800 mg/L), large in size yet lightweight. These particles cause severe erosion and corrosion to the pump's flow components, resulting in significant wear and tear on the pump's sealing rings. After just one month of continuous operation, the clearance between the sealing rings has already expanded to about 1.5 mm, leading to a noticeable decline in both flow rate and sealing performance. As a result, the pump must be shut down for maintenance—a process that not only disrupts system operations and impacts production but also drives up maintenance costs.

Currently, high-pressure grey water circulation pumps mostly utilize radially split multistage centrifugal pumps. DF-Type Stainless Steel Corrosion-Resistant Multistage Chemical Pump , The single-stage impeller design leads to deteriorated cavitation performance and reduced pump efficiency when operating at high flow rates, ultimately shortening the pump’s service life. Additionally, continuous erosion and wear caused by the medium disrupt the rotor’s dynamic balance, resulting in impeller component wear, imbalance of the balance disc, and increased pump vibration—significantly cutting down the equipment’s operational lifespan. Under high-pressure conditions, multi-stage pumps featuring a radial split design are prone to interstage seal failure, leading to leakage that, in severe cases, can severely impact production operations and economic efficiency.

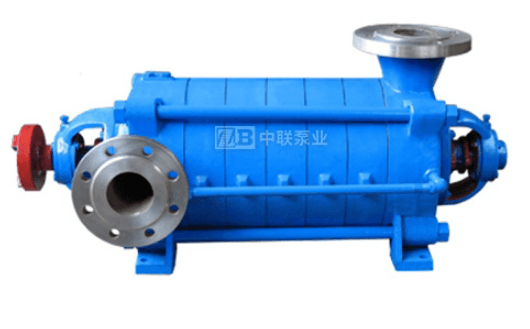

↑Click the image to learn about the DFP-type self-balancing system Multi-stage centrifugal chemical pump Product details and Price Information ↑

High-pressure grey water circulation pump model selection:

The high-pressure grey water circulation pump, designed to withstand high temperatures and pressures, primarily considers the hydraulic performance of the pump’s flow components (impeller and pump casing), the pump’s structural design, the material selection for pressure-bearing parts, as well as the sealing structure and materials. Additionally, factors like the bearing housing assembly’s design, bearing type, lubrication method, and cooling approach are carefully evaluated. Secondly, it’s crucial to address the balance of axial and radial forces both during the pump’s no-pressure commissioning at the inlet and under pressurized operating conditions. Finally, the choice of sealing mechanism, along with appropriate cooling and flushing methods, must also be taken into account.

Zhonglian Pump Industry, a centrifugal pump manufacturer, recommends the newly developed, highly efficient, high-pressure, multi-stage DFP-type self-balancing, corrosion-resistant centrifugal pump. Made from cast stainless steel, this pump boasts exceptional corrosion resistance and can handle applications involving hot water, oils, corrosive substances, or even abrasive media—up to temperatures of 225°C—by simply adjusting the pump’s material (and structural design), sealing options, and incorporating an advanced cooling system. Available materials include HT200, QT600-3, ZG, 304, 304L, 316L, 317L, 904L, and CD4, allowing users to select the most suitable material based on the specific medium being conveyed.

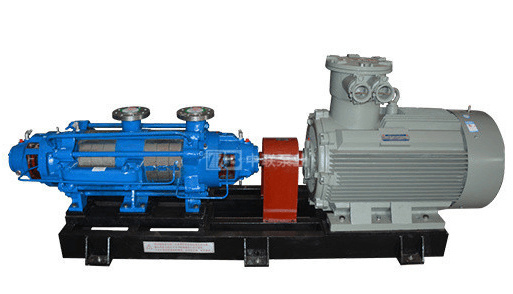

↑Click the image to learn about the DFP-type self-balancing, corrosion-resistant chemical pump Product details and Price Information ↑

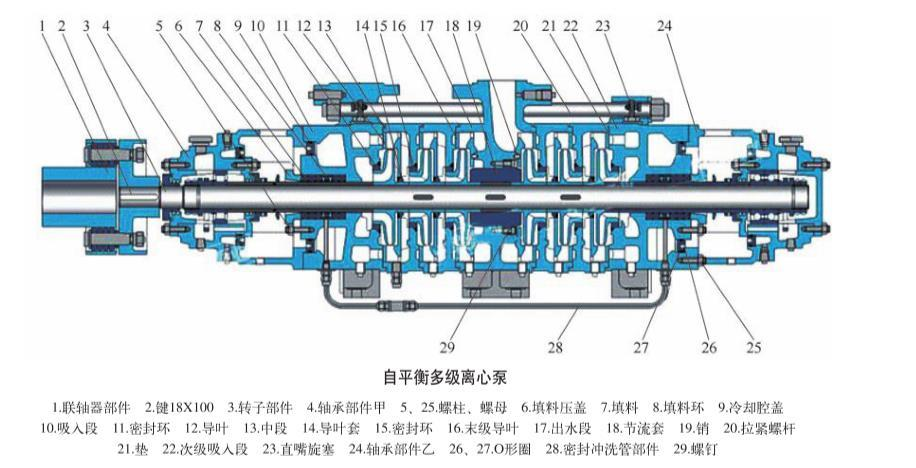

The DFP-type greywater circulation pump is a high-pressure, self-balancing multistage centrifugal pump (see the figure below), featuring a rotor assembly with symmetrically arranged impellers. The axial forces generated by each stage of impellers counterbalance one another—specifically, the forward axial force F1 equals the backward axial force F2—thus eliminating the need for a balance disc or balance drum design to achieve axial force equilibrium in the rotor assembly. In addition, the DFP-type greywater pump incorporates a thrust bearing at the pump’s discharge end, which effectively handles both transient and residual axial forces. This ensures that, during pump start-up, shutdown, or when system operating conditions fluctuate, the thrust bearing can reliably withstand substantial axial loads, safeguarding the pump from potential damage.

The DFP-type high-pressure symmetrical multistage pump boasts a 5% to 14% higher efficiency compared to other pumps in the same category, thanks to its unique design—specifically, it features no balance device, eliminating both disc friction losses from the absence of a balance disk and recirculation losses from balancing water. Moreover, with no friction occurring in the balance disk, the pump’s shaft power consumption is reduced, leading to significant energy savings. As a result, the pump consumes approximately 3% less electricity during operation than comparable multistage pumps. Additionally, this innovative design completely addresses common issues caused by balance device failures, such as wear on the balance disk and balance ring or even rotor seizure. By extending the pump’s service life dramatically—enabling trouble-free operation for more than three times longer than conventional pumps—the product significantly cuts down on maintenance costs for users, ultimately lowering the overall lifecycle cost of the pump. Years of successful operation have demonstrated that this product delivers performance levels that are on par with, if not surpassing, those of advanced international counterparts.

Previous:

Next:

Recommended Information

Related Products