The QW-type submersible sewage pump, commonly known as the QW submersible sewage pump, is a highly efficient, non-clogging submersible pump designed with key components including an impeller, pump body, and submersible motor base. Its rational design, coupled with a properly matched motor, ensures high efficiency and remarkable energy-saving performance. This pump model represents our company's latest product development. Featuring a unique single-channel impeller and employing two sets of advanced hard-alloy mechanical seals made from special materials, the pump’s oil-sealed motor compartment effectively prevents clogging while delivering exceptional efficiency and significant energy savings. As a cutting-edge upgrade in China’s pump technology, this product has earned widespread acclaim and positive feedback from users.

The QW-type submersible sewage pump shares the same shaft with its motor. Since the pump is positioned at the very bottom of the entire drainage unit, it can efficiently suction up residual wastewater from large areas. It is ideally suited for handling media with temperatures not exceeding 50°C and a pH range of 4 to 10, while also capable of conveying solid particles with diameters ranging from 15 to 110 mm and fibers whose length reaches up to 5 times the diameter of the pump inlet. This product is widely used in municipal projects, construction engineering, industrial and mining enterprises for wastewater discharge, as well as in hospitals, hotels, and residential areas for sewage disposal. The product complies with the Q/TBJW2-2003 standard titled "Submersible Electric Pump for Sewage and Sludge."

QW Model Submersible Sewage Pump Specifications

Flow range: 2–1500 m³/h

Head range: 3–45 m

Rotational speed n: 970–2900 r/min

Ambient temperature T: ≤ +40℃

Medium temperature: -15℃ to +60℃

Medium density: ≤1.3 × 10³ kg/m³

Medium pH range: 5–9

System maximum working pressure: ≤0.6 MPa

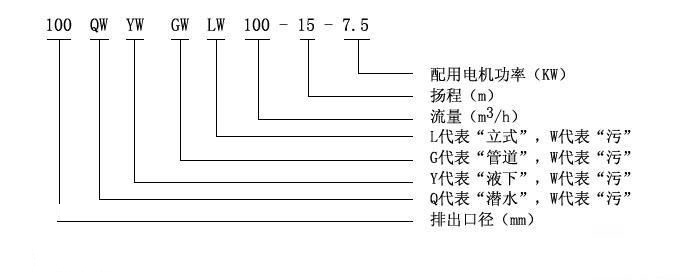

Model Description: 100QW110-10-7.5

100—Pump discharge diameter is 100 mm

QW——Submersible Sewage Pump

110——Design flow rate is 15 m³/h

10——Design head is 10m

7.5 – Motor power: 3 kW

Features of the QW Series Submersible Sewage Pump

3. Multi-channel detection and protection: Oil-water probes and float switches can both perform real-time monitoring, enabling functions such as alarm activation, machine shutdown, and retention of fault signals—ensuring the safe and reliable operation of the submersible motor.

4. Strong overcurrent capability: The dual-flow channel design ensures high pump efficiency and prevents clogging.

5. Convenient Maintenance: The coupling device, featuring dual rails, eliminates the need for underwater operations during pump installation and removal, making maintenance quick, easy, and highly efficient—saving both time and labor.

QW-Type Submersible Sewage Pump: Structural and Performance Characteristics

Previous:

Recommended Information

Related Products