Service Support

High quality, excellent service, and pursuit of development.

Solution

Solving user problems and core technological innovation are the key development strategies of the company. Changsha Zoomlian Pump Co., Ltd. has a new product R&D center and a CAD/CAE design system, with independent development, design, and research capabilities for water pumps. For many years, it has maintained a development path that combines traditional and new products, and vigorously promotes the brand strategy.

In the digital age, the intelligent pump management and maintenance system is finally here!

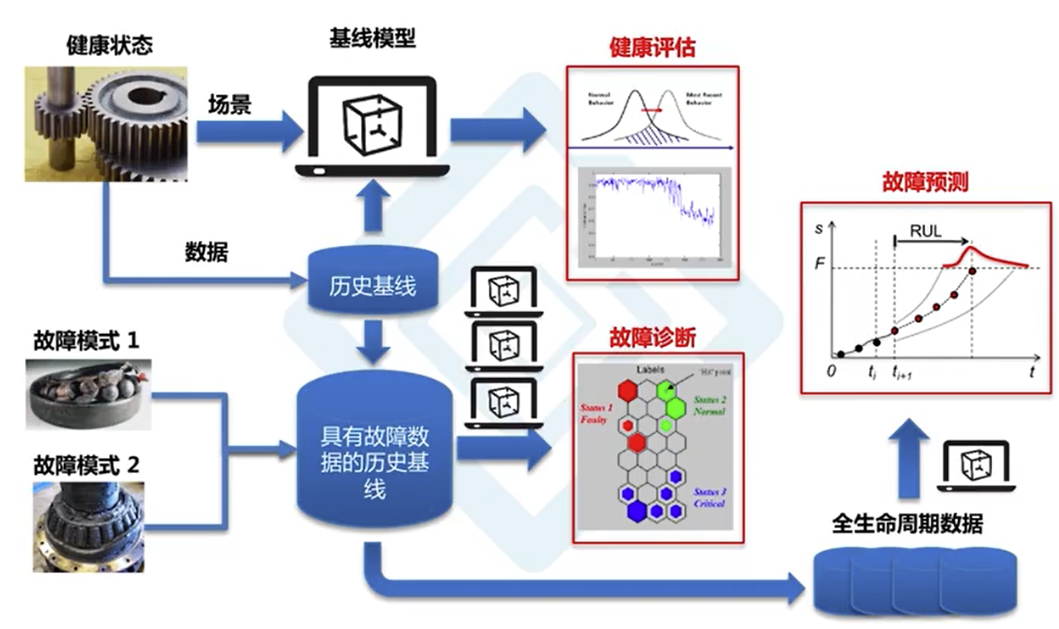

Against the backdrop of Industry 4.0, the intelligent and digital transformation of equipment has become the key to enterprises' upgrading and transformation. Changsha Zoomlion Heavy Industry Science & Technology Co., Ltd.'s newly launched "Smart Pump Butler" system is an innovative response to this trend, designed to enhance the operational and maintenance efficiency of pumping station equipment through cutting-edge technologies, enabling early fault diagnosis and proactive preventive maintenance.

05

2025-09

Zhonglian Pump Industry's Deep Well Pumps, Submersible Pumps, and Submersible Sewage Pump Series

The QJ-type stainless steel submersible well pump

Manufactured by Zhonglian Pump Industry, the QJ-type stainless steel submersible well pump is a new high-end product developed and produced using advanced U.S. and Italian technology and equipment for brushless electric pumps. The main components of the unit are crafted from stainless steel and copper alloy, offering high efficiency, energy savings, excellent wear resistance, rust prevention, zero pollution, and an aesthetically pleasing design—plus, it’s incredibly easy to install and use. This pump is especially ideal for extracting groundwater in factories, schools, and rural areas, making it the top-choice, most reliable equipment for geological and hydrological projects, as well as industrial, residential, and irrigation applications requiring efficient groundwater extraction.

05

2025-09

In addition to using multistage centrifugal pumps to drain water from mine shafts during the mining process in the coal industry, various types of pumps are also employed in coal preparation plants when washing coal after it’s extracted. In fact, pumps play a crucial role in nearly every coal-related industry. Today, Changsha Zhonglian Pump Industry, a leading pump manufacturer, will introduce you to the specific pumps used in the coal-washing process at coal preparation plants, helping customers gain a deeper understanding of how these pumps function in such applications.

Click on the image to learn more about Changsha Zhonglian!

05

2025-09

1. Core Basis for Selection and Specification Requirements 1. Drainage Capacity Calculation According to the "Coal Mine Safety Regulations" and related national standards, the pump selection must meet the following capacity requirements: Total capacity of working pumps: must discharge the normal 24-hour inflow of the mine within 20 hours. Backup pump capacity: not less than 70% of the working pump capacity, and the total capacity of working + backup pumps should be within 20 hours.

05

2025-09

The "Heart" of the Oilfield: Revealing How Water Injection Pumps Continuously Inject the "Water of Life" into the Reservoir Beneath the vast oilfield, crude oil does not flow out continuously on its own. As extraction proceeds, the formation pressure gradually decreases, like a slowly deflating balloon, unable to push the oil from deep underground to the wellhead. At this time, a powerful "heart" is needed—the oilfield water injection

28

2025-08