Product Overview

Ammonia water is an aqueous solution of ammonia, appearing colorless and transparent with a pungent odor. Ammonia gas is highly soluble in water and ethanol, readily volatile, and exhibits some of the typical properties of a base. Ammonia water is produced by bubbling ammonia gas into water. Ammonia gas is toxic, irritating, and corrosive; it particularly attacks copper strongly, while its effect on steel is relatively mild. Therefore, it’s essential to use specialized ammonia pumps designed specifically for transporting ammonia water, ensuring efficient circulation within the ammonia system.

Features of the Ammonia Water Pump

Ammonia water is volatile and irritating. Both the pump seal ring and the sliding vanes are made from a special foreign formulation, offering exceptional wear resistance, toughness, and strength. The pump casing is crafted from high-density, highly corrosion-resistant alloy cast iron, ensuring a smooth, polished finish after machining. The pump employs a mechanical seal, with a filled PTFE stationary ring replacing the traditional graphite ring—effectively resolving ammonia pump leakage issues and significantly extending the pump's service life. This, in turn, guarantees that ammonia liquid remains completely contained without any leaks. A key feature of this ammonia water pump is its excellent sealing performance, zero leakage, high pressure capability, and stable, reliable operation.

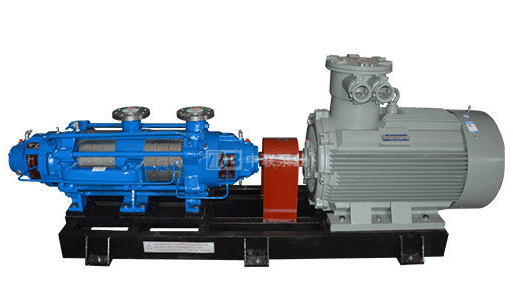

Most ammonia pumps on the market utilize a multi-stage centrifugal design, and Zhonglian Pump Industry strongly recommends them. DF(P)-Type Corrosion-Resistant Self-Balancing Multistage Pump , it employs the nationally recommended high-efficiency and energy-saving hydraulic model, achieving 8,000 consecutive hours of trouble-free operation. Featuring a design without balancing devices, this pump is crafted from stainless steel, offering excellent corrosion resistance and superior sealing performance. It delivers exceptional energy efficiency while ensuring practical safety, economic benefits, reliable fault-free operation, and significantly reduced maintenance costs. This makes it an ideal, modernized replacement for ammonia pumps that traditionally use a balance disc structure.

Application Scope of Ammonia Pumps

Primarily used for transporting volatile liquids with similar properties, such as liquid ammonia, ammonium hydroxide, methanol, dimethylamine, propylene oxide, crude benzene, ethylene oxide, chloromethane, isobutylene, butadiene, and more—these applications are widely found in industries like gas supply, petroleum, chemical processing, pharmaceuticals, metallurgy, and beyond.

Ammonia Pump Shaft Seal

Employing indirect drive via internal and external magnetic forces, the system completely eliminates the traditional shaft seals found in centrifugal pumps. Instead, a stainless steel sleeve paired with a fluoroplastic isolation liner provides a robust barrier between the inner and outer magnets, ensuring truly zero-leakage operation. This design offers unparalleled reliability when handling flammable, explosive, volatile, or valuable liquids, while virtually eliminating the need for maintenance during operation.

The Application of Frequency Conversion for Energy Saving in High-Pressure Ammonia Pumps

During coke oven production, to prevent large amounts of smoke and dust from escaping through the coal-charging holes and polluting the atmospheric environment, it is common practice to inject high-pressure nitrogen water into the bridge pipe, creating a slight negative pressure at the base of the riser. This helps guide the raw gas into the gas collecting main, thereby minimizing the leakage of unburned gas and dust into the atmosphere. When injecting high-pressure ammonia water into the bridge pipe, maintaining a consistent pressure is crucial. If the pressure is too low, the smoke-extraction effect will be inadequate; conversely, if the pressure is too high, excessive air and dust may enter the gas collecting main, leading to an overabundance of oxygen in the gas and increasing the risk of blockages in the gas pipelines.

According to the fundamental laws of fluid mechanics, pressure is proportional to the square of the rotational speed, while power is proportional to the cube of the rotational speed. Therefore, if the motor's rotational speed can be reasonably reduced—while still meeting production requirements—this becomes a crucial approach to energy conservation for water pumps.

First, the frequency converter must be configured based on the motor parameters of the coking high-pressure nitrogen water pump and the technical requirements of the controlled object. By utilizing the built-in PID controller of the frequency converter, along with a pressure transmitter installed on the ammonia-water pipeline, a closed-loop automatic control system is established to implement PI control over the nitrogen-water pressure. (Note: When the derivative time parameter is set to zero, no differential control is applied.) The principle works as follows: The actual ammonia-water pressure in the pipeline is converted into an analog electrical signal via the pressure transmitter, which is then sent back to the frequency converter for comparison with its internal pressure setpoint. Based on the resulting deviation, the PID algorithm calculates the necessary adjustments, enabling the frequency converter to dynamically regulate the motor speed in real time. This ensures a stable ammonia-water supply pressure at all times.

Through actual operational observations, it was found that if completely shut down Multistage centrifugal pump During the intervals of coking oven coal-charging operations, the bypass reflux valve keeps the motor speed steady at 23 kll/min, while the nitrogen-water pipeline network remains pressurized. However, if the coking oven undergoes maintenance or other extended periods when coal-charging operations cannot take place, the high-speed rotating impeller will rub against the stationary ammonia water inside the pump. This friction causes the nitrogen-water mixture to heat up and vaporize within the pump, leading to bubble formation that moves unpredictably through the pipelines. As a result, the pressure transmitter may fail to accurately detect the actual nitrogen-water pressure, creating significant disturbances in the closed-loop automatic control system. Consequently, this can cause the frequency converter to abruptly fluctuate the motor speed—alternating between sudden increases and decreases. To address this issue, even when employing variable-frequency drives for constant-pressure PD control, it remains necessary to keep the bypass reflux valve partially open; however, the valve opening can be appropriately reduced to minimize unnecessary flow.

Because the lower rotational speed prevents nitrogen water from vaporizing inside the pump, the bypass reflux valve can be completely closed, further reducing electricity consumption. In actual operation, to ensure that the ammonia water pressure briefly meets production requirements during coal-loading operations in the coke oven, the frequency output of the variable-frequency drive is set to 25 Hz when running at low speed. Operating in this manner significantly helps conserve energy.

Previous:

Recommended Information

Related Products