The steam drum serves as the crucial link connecting the three key processes of working fluid heating, evaporation, and superheating, ensuring proper water circulation within the boiler. Meanwhile, the boiler itself is a quintessential example of a complex thermodynamic control system. Among its critical parameters, the water level in the steam drum is vital for maintaining safe and stable boiler operation. Moreover, it acts as a reliable indicator of whether the mass balance in the boiler's steam-water system is maintained. Consequently, keeping the steam drum water level within the prescribed range is one of the primary indicators of normal boiler operation.

The boiler bubble feedwater system relies on a bubble feedwater pump to inject water into the economizer, where it is heated to become saturated water at the working pressure of the steam drum. This water then flows into the steam drum and, via the downcomers, enters the water-cooled walls surrounding the furnace. There, it absorbs heat from the furnace, causing it to vaporize. The resulting steam rises through the riser tubes back to the steam drum, where it is separated from the remaining saturated water. The purified steam is then sent to the superheater, where it absorbs additional heat from the flue gases, transforming into superheated steam before being routed to the steam turbine for continuous power generation. At the heart of this system lies the boiler bubble feedwater circulation pump, which ensures the smooth and efficient operation of the entire steam drum system.

Boiler Bubble Feedwater Pump Model Selection

Depending on the application, boiler feed pumps are typically selected based on boiler pressure: low pressure refers to pressures below 2 Pa, medium pressure falls between 2 and 6 Pa, and high pressure indicates pressures greater than 6 Pa. Boiler steam drum feed pumps are mainly categorized into two types—medium- and low-pressure boiler feed pumps, as well as high-pressure boiler feed pumps. When selecting a pump model, users can choose the most suitable one according to their specific operational requirements. Commonly used boiler feed pumps are centrifugal pumps; however, for low-pressure boilers, vortex pumps may also be chosen to reduce initial investment. That said, most boiler feed pumps still opt for multistage centrifugal pumps. Currently, there are two main types of multistage pumps available: vertical multistage pumps and horizontal multistage pumps. Among these, horizontal multistage centrifugal pumps are increasingly preferred due to their outstanding features, such as high efficiency, energy savings, stable operation, reliable mechanical seals that prevent leakage, and minimal noise levels.

The GC-type low-pressure boiler feedwater pump is a horizontal, single-suction, multistage, sectional centrifugal pump, primarily used for boiler feedwater applications—hence its alternative name, boiler feedwater pump. This series of boiler feedwater pumps is suitable for conveying clean water at temperatures below 110°C, as well as other non-corrosive liquids with physical and chemical properties similar to water. They are widely employed in boiler feedwater systems for industrial, mining, and institutional facilities, as well as in urban municipal water supply systems. The pumps boast high efficiency, a broad performance range, safe and stable operation, low noise levels, long service life, and convenient installation and maintenance. However, the GC-type bubble feedwater pump is considered an older, outdated model and is no longer commonly used in the market.

↑Click the image to learn about the GC-type low-pressure boiler bubble feedwater pump Product details and Price Information ↑

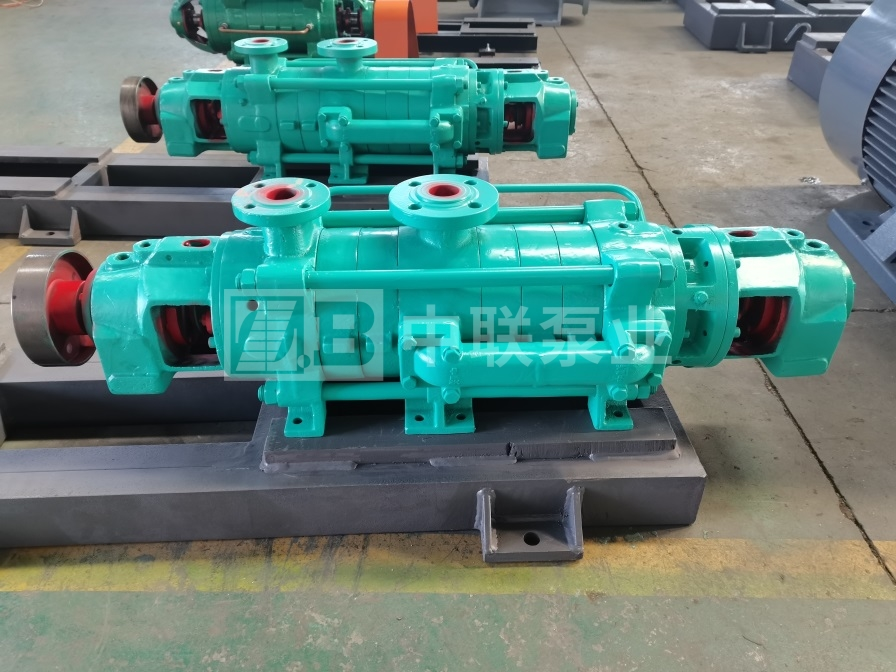

The DG-type medium- and low-pressure multistage boiler feedwater circulating pump features a multistage centrifugal design. It is an efficient and energy-saving product specifically developed to upgrade and retrofit modern industrial steam boilers, serving as the ideal choice for boiler feedwater applications. With exceptional pressure resistance and reliability, this pump is designed to handle clean water or other non-corrosive liquids—similar in physical and chemical properties to water—without solid particles, at temperatures ranging from -20°C to 210°C. Please note that the inlet pressure of the DG-type feedwater circulating pump must not exceed 0.59 MPa (6 kgf/cm²), making it suitable for medium- and low-pressure feedwater systems. The materials used for the pump’s wetted components—including cast iron, cast steel, and cast stainless steel—are selected based on the temperature of the fluid being conveyed. Moreover, the DG-type feedwater pump incorporates a nationally recommended, highly efficient and energy-saving hydraulic model, offering a wide performance range, superior operational efficiency, and extended service life. As a result, it effectively replaces the older GC-type boiler feedwater pumps.

↑Click the image to learn about the DG-type boiler bubble feedwater pump Product details and Price Information ↑

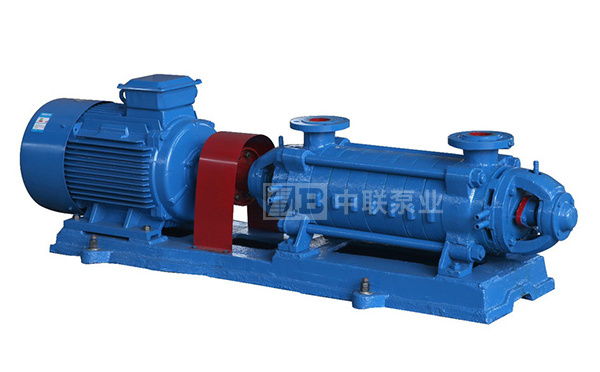

The DGP-type self-balancing high-pressure boiler feedwater pump is an efficient, high-pressure multistage centrifugal pump developed by our company, Changsha Zhonglian Pump Industry, in accordance with the API610 standard. Designed for use as a high-pressure boiler steam drum feedwater pump or other high-pressure water supply applications, this pump can handle media temperatures ≥200°C and deliver head heights ≥1680 meters. Structurally, it features a horizontal installation and employs a single-casing, sectional multistage centrifugal design, ensuring smooth operation, easy installation and maintenance, and making it ideal for unit-based and main-pipeline feedwater systems in power plants of various capacities.

↑Click the image to learn about the GDP-type self-balancing system Boiler steam bubble feed pump Product details and Price Information ↑

The DGP-type self-balancing high-pressure boiler steam-driven feedwater pump features an innovative design based on the conventional multistage centrifugal pump structure. It eliminates the axial force balancing mechanism typically found in multi-stage centrifugal pumps, making it an excellent replacement for D- and DG-type multistage centrifugal pumps that rely on balance discs or balance drums. Because this pump is equipped with no balancing device—meaning there’s neither disc friction loss from a balance disc nor recirculation losses associated with a balance drum—it achieves a 5-14% higher efficiency compared to similar multi-stage pumps. At the same time, it completely resolves various issues caused by the failure of traditional balancing systems, such as wear on the balance disc and its seat, or even rotor seizure, thereby significantly extending the pump’s service life.

Bubble-driven water pump bearings and balancing devices

The rotor of the DG-type medium-pressure bubble feedwater pump is supported by rolling bearings at both ends of the pump shaft. It is lubricated with dilute oil and cooled using circulating water. Axial thrust on the rotor is automatically balanced by a balance disc. The balancing water returns to the pump suction section via the return pipe.

The rotor of the DG-type, high-pressure steam-driven feedwater circulation pump is supported by sliding bearings located at both ends of the pump shaft. It is lubricated with thin oil and cooled by circulating water. The axial thrust of the rotor is balanced by a balance disc, and a return pipe is installed between the balance chamber and the front section.

The rotor of the DGP-type high-pressure steam drum feedwater pump is supported by sliding bearings located at both ends of the pump. The bearings are lubricated by forced circulation, and the pump itself is equipped with an oil system. Axial thrust on the rotor is balanced by a balance disc, and the design also includes a thrust bearing to handle any residual axial forces that may arise due to operational condition changes. Additionally, a return pipe is installed between the balance chamber housing and the suction pipe.

Next:

Recommended Information

Related Products