I. Overview of the Coke Quenching Pump:

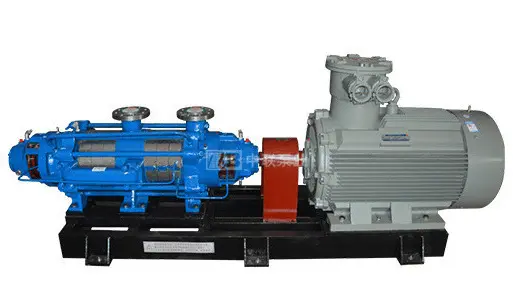

With the rapid development of industry, coking enterprises have gradually expanded in scale, and metallurgical coke technology continues to evolve and improve. Coke quenching is a critical step in the production of coke. Although dry quenching technology is now available—albeit with limited processing capacity—a significant portion of coke still requires traditional wet quenching. Among these methods, residual ammonia water quenching remains a commonly used approach. The quenching pump is the primary essential equipment in the wet quenching process, and most coking plants currently rely on quenching pumps of this type. Double-suction centerline pump 。

↑Click the image to learn about the double-suction split-case pump Product details and Price Information ↑

While the water-quenching method—using water to cool down the scorching coke—has several drawbacks, such as wasteful consumption of water resources, the severe risks posed by steam containing coke dust that can solidify and fall back onto equipment and even harm human health, and the inefficient utilization of the thermal energy from quenching water, it remains highly favored due to its low cost and ease of installation and operation. Therefore, the operational status of the quenching water pump directly affects both the quality of the coke and the smooth execution of the quenching process.

In practical operation, pumps are not easily damaged, but they are prone to leakage, which not only wastes water resources but also significantly affects the quenching process and the moisture content of the coke. When pump leaks enter the bearing housing, they can lead to bearing failure, wear on the bearing pedestal, as well as damage to the pump shaft and sleeve—resulting in breakdowns that necessitate production shutdowns for repairs. This disrupts the smooth flow of continuous operations, severely impacting the company’s economic efficiency and causing substantial losses. At the same time, the workload and costs associated with maintenance efforts also become considerable. Therefore, preventing leakage from coking quenching pumps is of paramount importance.

II. The Impact of Residual Ammonia Water from the Coke Quenching Pump on Coke Quenching:

The coking quenching pump system primarily consists of the quenching tower, quenching pumps, and their associated pipelines. In the absence of biochemical treatment for coking wastewater, the quenching water is mainly sourced from residual ammonia water. However, using ammonia water for quenching has several drawbacks—such as the steam containing coke fines, which can severely damage mechanical equipment, and also pose significant risks to human health.

The process of quenching coke is roughly as follows: As the coke-quenching car enters the quenching tower, infrared sensors detect the infrared signals emitted by the glowing coke itself, triggering a signal current that activates the quenching water pump via an amplification circuit. An electronic timer then precisely controls the duration of the quenching process. After quenching, the cooled coke is unloaded onto the cooling platform, where it rests for 30 to 40 minutes to allow moisture to evaporate and the material to cool further. Any remaining unextinguished red-hot coke pieces are manually doused with water to ensure complete extinguishing. Currently, without biochemical treatment in place, leakage from the quenching pumps has become the most troublesome issue. Below is an analysis of the quenching pump leakage problem.

III. Multiple factors contribute to the coke quenching pump leakage:

1. Composition of Residual Ammonia Water

Due to the low oil-removal efficiency of the solvent dephenolization and oil-separation system, the remaining ammonia water still contains a high oil content even after oil removal. When this water enters the solvent dephenolization system, it quickly causes emulsification of the extractant—heavy benzene, leading to heavy loading on the regenerator, frequent sludge discharge, reduced dephenolization efficiency, and increased extractant consumption. Moreover, because the oil concentration in the post-dephenolization ammonia water remains excessively high, it cannot be directly fed into the ammonia-washing system; instead, it must be sent to the aeration tank, impairing the adsorption capacity of the activated sludge and ultimately lowering the efficiency of biological dephenolization. At the same time, a portion of the remaining ammonia water is directly routed to biochemical treatment, requiring more than 10 times the volume of dilution water. This not only results in significant consumption of dilution water but also increases the volume of wastewater discharged. Additionally, the gravity sedimentation filter used for oil removal has a very low efficiency—only about 30%—leaving approximately 80 mg/L of tar in the enriched ammonia water even after oil removal. As a result, the ammonia distillation tower must be shut down roughly every six months for dismantling, inspection, and cleaning, which places a heavy burden on workers, drives up maintenance costs, and ultimately reduces the plant’s operational availability.

2. The Necessity of Process Management

In terms of management, there are still some areas that fall short—specifically, the separation of clean and contaminated wastewater remains inadequate. Additionally, certain aspects of the process technology are not entirely rational. These issues have resulted in an inflow of 50 m³/h or more of wastewater into the biochemical system. Moreover, the ammonia content in the steam-ammonia wastewater is around 600 mg/l, requiring a 1:3 dilution with fresh water before it can be fed into the biochemical treatment system. This process consumes 150 m³/h of fresh water per hour, leading to effluent from the biochemical system that exceeds the allowable limits for ammonia nitrogen and COD. Based on practical considerations and after careful analysis, we have decided that, under current conditions, zero discharge of phenol- and cyanide-containing wastewater can be achieved by implementing targeted technical upgrades and pollution-reduction measures during the production process.

The tar and ammonia water exiting the gas-liquid separator enter the mechanized tar-ammonia clarification tank. After thorough clarification and separation, the upper-layer ammonia water is sent to the circulating ammonia tank, where it is pumped—via the circulating ammonia pump and the high-pressure ammonia pump—to the coking section for cooling raw gas, purging the gas collecting main, and supplying steam for smokeless coal charging. Meanwhile, the remaining ammonia water is conveyed by the residual ammonia pump to the sulfur ammonium section for ammonia evaporation. The separated tar is stored in the intermediate tar tank; once it reaches a certain liquid level, a tar pump transfers it to the main tar tank.

3. Selection of Sealing Gaskets

When the packing experiences uneven radial deformation under axial force, the following situation occurs: The packing rings initially make local contact with the shaft surface along the circumference of the shaft. As the packing continues to deform in this area, it forms a high-stress contact zone with the shaft. This region generates significant frictional heat, causing temperatures to rise dramatically. To prevent overheating, the stress must be reduced. Meanwhile, the lower-lying areas may remain either uncontacted or fail to achieve a reliable seal altogether, ultimately leading to leakage and compromising the overall sealing performance of the packing.

Due to the aforementioned characteristics of packing, it is often necessary to maintain a certain level of leakage when sealing equipment; otherwise, the packing may overheat. With repeated tightening of the gland, the fiber bundles within the packing gradually align uniformly, causing the packing to lose its ability to deform and ultimately leading to seal failure. Moreover, the braided structure of the packing material results in an uneven surface, preventing microscopic, continuous, planar contact with the shaft—and thus creating leakage pathways from the very beginning. Additionally, there are several drawbacks during the quenching process: for instance, significant steam is generated during quenching, which increases the need for water replenishment, resulting in wastage of water resources. Furthermore, the process produces large amounts of airborne particulates, polluting the environment and posing potential health risks to humans.

IV. Recommendations for Coking Quench Pump Selection:

Through observation and research on the ammonia quenching pump, we identified the root cause of the leakage issue. Ammonia quenching not only leads to severe corrosion of the quenching cars, resulting in high maintenance costs, but also causes significant erosion to the quenching pumps themselves, frequently causing leaks that disrupt their normal operation. These issues during the quenching process have prompted us to conduct a focused discussion and thorough investigation. Our analysis reveals that to effectively reduce or eliminate the leakage in the ammonia quenching pump, it is crucial to enhance the sealing performance of the packing material. Moreover, improving the structural design of the pump is essential for addressing this problem head-on. Ultimately, no matter which approach is taken, the packing must maintain continuous, smooth, and even contact with the shaft surface—only then can optimal sealing performance be achieved.

Therefore, when selecting a coke quenching pump, the primary consideration should be its sealing performance. Most pumps on the market are double-suction pumps, but their seals are often unreliable. However, Zhonglian Pump Industry's Self-balanced multistage pump Product: DF(P)-Type Corrosion-Resistant Self-Balancing Multi-Stage Quenching Pump. Leveraging the unique characteristics of quenching pumps, this model incorporates mechanical sealing and dual-sealing technology—featuring a labyrinth seal at the front end and a magnetic seal at the rear. The pump boasts a secure, robust sealing design with highly reliable mechanical seals. Additionally, during pump startup and shutdown, the rotor components remain free from axial movement, ensuring stable operation without any axial pulsation. This innovative design effectively addresses the longstanding challenges of poor mechanical seal reliability and frequent leakage issues that have long plagued quenching pumps.

↑Click the image to learn about the DF(P)-type corrosion-resistant, self-balancing multistage pump Product details and Price Information ↑

Problems that arise during the coke quenching process can be addressed by adopting low-moisture quenching technology. This technology replaces the original splash-type spray pipes with high-flow, large-aperture atomizing nozzles imported from overseas, significantly enhancing atomization efficiency and ensuring more uniform spraying. As a result, it helps shorten quenching time, reduce moisture content, and minimize the amount of red coke produced. Moreover, this quenching method is simple to implement, requires minimal investment, and is easy to retrofit.

V. Operation and Effects of the Coke Quenching Pump Retrofit

Through the renovation and analysis of the coke quenching pump, the leakage issue has been resolved. This not only boosts coke production output but also significantly reduces manufacturing costs, enhances operational efficiency, and saves considerable labor and material resources. Additionally, the improved working environment has led to a substantial increase in overall productivity and profitability.

Previous:

Recommended Information

Related Products