The highly corrosion-resistant pump is a widely used chemical pump product in the industrial sector. As its name suggests, it is a chemically resistant pump with exceptional durability against corrosive substances, making it ideal for transporting liquids that are inherently corrosive. This type of pump is particularly suited for industries such as petroleum, chemical processing, fertilizer production, synthetic fibers, power generation, metallurgy, papermaking, mining, light textiles, pharmaceuticals, sugar manufacturing, acid and alkali production, food processing, and environmental protection—enabling the efficient conveyance of acids, bases, oils, rare and precious liquids, toxic substances, and even volatile, highly corrosive chemical media at any concentration.

The most widely used materials for transporting highly corrosive liquids are stainless steel and fluoroplastic, which are employed in corrosion-resistant centrifugal pumps. These pumps offer advantages such as a broad corrosion-resistance range and convenient maintenance operations. As a manufacturer specializing in the R&D of centrifugal pumps, Changsha Zhonglian Pump Industry primarily produces highly corrosion-resistant pumps, including stainless steel models and fluoroplastic centrifugal pumps designed for extreme corrosive environments.

Stainless Steel Highly Corrosion-Resistant Pump Models

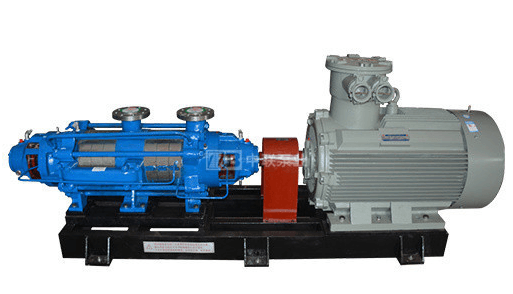

DF-Type Stainless Steel Highly Corrosion-Resistant Pump This is a horizontal, single-suction, multistage, sectional centrifugal pump designed for conveying corrosive liquids with temperatures ranging from -20°C to 105°C—liquids that contain no solid particles. The pump's inlet is rated to withstand pressures up to 0.6 MPa. The flow components of the DF-type highly corrosion-resistant pump are all made of stainless steel, as is the shaft. As for sealing mechanisms, the pump offers both packing seals and mechanical seals. Packing seals are primarily used in applications where leakage requirements are not stringent or when the medium contains solid particles. In contrast, mechanical seals are ideal for high-temperature, high-pressure, and corrosive environments where strict leakage control is essential. Both types of seals effectively seal the pump at both ends, preventing the internal medium from leaking out while ensuring the overall integrity and reliability of the pump's containment system. With the exception of the DF155-30 and DFHG models, which feature horizontal suction and vertical discharge, all other DF-type pump models are designed with vertical suction and vertical discharge configurations.

↑Click the image to learn about the horizontal stainless steel corrosion-resistant multistage pump Product details and Price Information ↑

DF(P)-Type Self-Balancing Stainless Steel Highly Corrosion-Resistant Chemical Pump Zhonglian Pump Industry has innovated the structural design of traditional multistage centrifugal pumps by adopting an advanced impeller hydraulic model or a unique dual-stage impeller configuration, resulting in a new generation of highly efficient, energy-saving chemical centrifugal pumps equipped with a revolutionary no-balancing device. These pumps are precision-cast from stainless steel and are specifically designed to handle corrosive liquids—free of solid particles—with temperatures ranging from -20°C to 80°C. They boast exceptional corrosion resistance, coupled with outstanding practical safety, economic efficiency, reliable fault-free operation, and remarkably low maintenance costs. Notably, thanks to the absence of a traditional balancing device (such as a balance disc), these pumps eliminate both disc friction losses and unnecessary recirculation-related inefficiencies. As a result, pump efficiency is improved by 5% to 14% compared to conventional multistage pumps featuring balance discs or balancing mechanisms. Moreover, this innovative design completely eliminates common failures—like wear on the balance disc and its seat, or even rotor seizure—that often occur due to the failure of traditional balancing systems, significantly extending the pump’s service life.

↑Click the image to learn about the DF(P)-type corrosion-resistant, self-balancing multistage pump Product details and Price Information ↑

FSB Series Fluoroplastic Highly Corrosion-Resistant Pumps It is a single-stage, single-suction cantilever centrifugal pump whose wetted parts are entirely made of fluoroplastics. The pump body features liner materials such as polyfluoroethylene propylene (F46) or polyvinylidene fluoride (F2), which can be selected according to the user's specific requirements. Meanwhile, the pump cover, impeller, and shaft sleeve are all integrally molded through overall sintering and pressing, with metal inserts encased in fluoroplastic. The shaft seal employs an external-type bellows mechanical seal, where the stationary ring is crafted from 99% alumina ceramic or silicon nitride, while the rotating ring is made of PTFE-filled material. This design ensures exceptional corrosion resistance and wear durability, making the pump ideal for conveying clear liquids like acids, bases, or solvents. The operating temperature range spans from -20°C to 100°C. Equipped with a state-of-the-art external-type PTFE bellows mechanical seal, this pump excels in compensating for radial runout of the pump shaft. Featuring a single-end face seal that is easy to install and disassemble, it offers intuitive monitoring of operational status, superior corrosion and abrasion resistance, and robust multi-layered protection—significantly extending the service life of the mechanical seal. For applications involving corrosive media containing solid particles, users can opt for a non-cooled, single-end hard-to-hard mechanical seal (silicon carbide against silicon carbide). For particularly aggressive media like strong alkalis or hydrofluoric acid, a pressureless-sintered silicon carbide seal is recommended. When selecting the appropriate model, users should carefully consider both the solid content in the medium and its unique corrosive properties. The FSB highly corrosion-resistant pump boasts exceptional chemical resistance, coupled with outstanding advantages such as high strength, excellent aging resistance, and complete absence of toxic decomposition.

↑Click the image to learn about the DF(P)-type corrosion-resistant, self-balancing multistage pump Product details and Price Information ↑

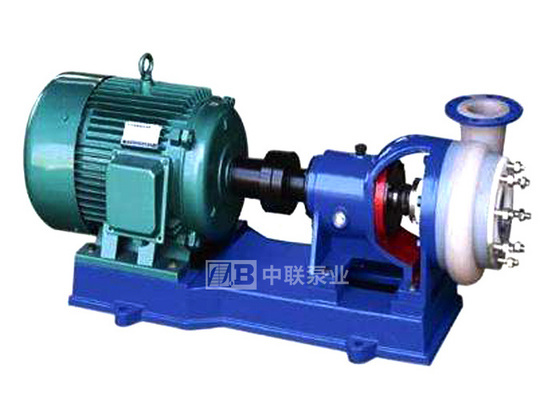

The IHF fluoroplastic-lined, highly corrosion-resistant chemical centrifugal pump is a next-generation, robustly corrosion-proof fluoropolymer centrifugal pump designed and manufactured based on the IH pump series, incorporating advanced processing techniques typically used for non-metallic pumps. The pump body features a metal casing lined internally with perfluoroalkoxy alkane resin (F46), while the pump cover, impeller, and shaft sleeve are all crafted by integrally sintering and molding fluoroplastic over metal inserts. The shaft seal utilizes a PTFE-filled material, and both the inlet and outlet ports are reinforced with cast steel components. The IHF series of highly corrosive-resistant centrifugal pumps combines the superior features of multiple types of chemical pumps, making them ideal for continuous operation under temperatures ranging from -20°C to 120°C. They are specifically designed to reliably handle a wide variety of corrosive media—such as acids, oxidizing agents, and other aggressive chemicals—at any concentration. These pumps boast exceptional durability, featuring resistance to corrosion, abrasion, and high temperatures; they also exhibit excellent aging resistance, high mechanical strength, smooth operation, an advanced and rational structural design, and highly reliable sealing performance. Additionally, their convenient disassembly and maintenance capabilities ensure long service life, making them widely applicable across industries including chemical processing, pharmaceuticals, petroleum, metallurgy, smelting, power generation, electroplating, dye production, pesticide manufacturing, papermaking, food processing, and textile industries. Moreover, these pumps excel in handling strong corrosive media such as sulfuric acid, hydrochloric acid, hydrofluoric acid, nitric acid, aqua regia, strong bases, powerful oxidizers, organic solvents, and reducing agents—under conditions ranging from -85°C to 200°C—and are currently recognized as one of the most corrosion-resistant equipment available worldwide.

The BF-type stainless steel, highly corrosion-resistant centrifugal pump is a single-stage, single-suction, cantilevered design, featuring performance parameters aligned with internationally advanced centrifugal pump standards—and cleverly customized to meet specific new user requirements. Its sealing components utilize an advanced mechanical seal system, while the pump body, pump cover, impeller, and other flow-path parts are crafted from either 1Cr18Ni9Ti stainless steel or other corrosion-resistant materials. The shaft seal assembly incorporates a cutting-edge mechanical seal configuration, equipped with imported titanium alloy sealing rings made from wear-resistant, high-temperature-resistant materials, effectively extending the service life of the sealing mechanism. This pump offers convenient installation and maintenance, available in both fixed and mobile models. Fixed models feature flanged connections at the inlet and outlet, whereas mobile models use quick-connect couplings for ease of operation. The pump boasts stable and reliable performance, excellent sealing capabilities, an aesthetically pleasing design, simple operation, compact size, lightweight construction, and easy-to-use maintenance features. It is designed to handle media temperatures ranging from 0°C to 105°C, and can be customized with appropriate sealing structures and materials tailored to customer specifications.

Previous:

Recommended Information

Related Products