Overview of the High-Pressure Ammonia Pump

As coal resources become increasingly exploited, high-quality coking coal is becoming scarce in the coking industry. Meanwhile, the use of gas coal and weakly caking coal can be significantly expanded through the adoption of top-charging coke ovens. Consequently, the advantages of top-charging technology are becoming more evident, making this process steadily favored by production enterprises. However, since coal charging in top-charging coke ovens is carried out through the machine-side furnace door, smoke emissions tend to be quite severe. To protect the environment, a widely adopted solution involves combining high-pressure ammonia pumps with dust removal vehicles. The high-pressure ammonia pumps deliver pressurized ammonia into the raw gas extraction system, effectively suppressing smoke and capturing dust during the coal-charging process, thereby achieving excellent environmental benefits.

● How a High-Pressure Ammonia Pump Works

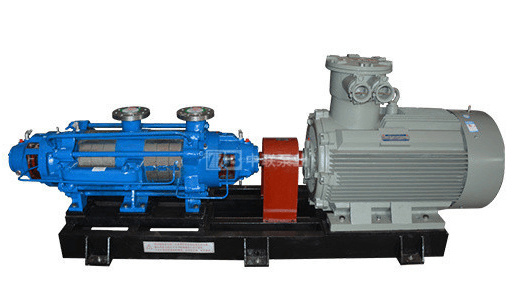

Almost all coke ovens utilize a high-pressure ammonia-free coal-charging system, and the primary function of the high-pressure ammonia pumps is to… Multistage centrifugal pump Ammonia water from the storage tank is pressurized and then sent to the coke oven bridge pipe, where it is sprayed out during coal-charging operations. When coal is loaded, the high-pressure ammonia valve opens the corresponding nozzle, instantly releasing the pressurized ammonia through the ammonia spray nozzles on the bridge pipe, creating a negative pressure beneath the coal-charging hole. Under this strong suction force, the substantial smoke, dust, and coal gas generated during the coal-charging process are drawn upward via the riser pipe, bridge pipe, and valve body, eventually entering the gas collecting main—thus enabling smoke-free coal charging.

● CNCEC Self-Balancing High-Pressure Ammonia Pump Requires No Balancing Device

Defects of conventional ammonia pumps:

(1) The balance disc of a standard high-pressure ammonia pump has poor impact resistance. When removing the balance disc before replacing the mechanical seal sleeve, the disc often cracks, causing ammonia water to leak from the resulting fissures.

(2) The bolt threads securing the motor and ammonia pump have partially failed, causing the ammonia pump casing to have excessive freedom of movement during operation, making it impossible to stabilize the pump body.

(3) The mechanical seal gland fastening bolts and bearing end cover fastening bolts, which have been subjected to ammonia corrosion over a long period, show severe rusting, leading to uneven force application during installation.

As a result, Zhonglian Pump Industry has developed High-Efficiency Self-Balancing Multistage Pump , it employs a design without a balancing device—eliminating both disc friction losses associated with the absence of a balance disk and the inefficiencies caused by balance reflux. This innovative approach removes axial force-balancing mechanisms such as balance disks or balance drums altogether, completely preventing failures of these components during transient changes in pump operation, as well as avoiding wear on the balance disk seats or potential issues like rotor seizure, component damage, shaft breakage, or even motor burnout. As a result, the pump's service life is significantly extended. Moreover, the equipment can operate fault-free for more than three times longer than conventional pumps, ensuring stable performance while dramatically reducing users' maintenance costs—and ultimately lowering the pump's overall lifecycle costs.

The impact of mechanical seal leakage on production equipment:

For double-end-face seals, if the outer end face leaks, it can be directly observed and has little impact on the production system. However, if the inner end face leaks, the leakage of sealing water into the ammonia system will significantly affect the production equipment.

(1) The heat generated during the reaction between ammonia and water, which forms ammonium hydroxide, causes the liquid ammonia temperature in the combined ammonia cooler to rise by 4°C, leading to an increase in pressure inside the vessel. This, in turn, results in a sudden and significant surge in the load of the ammonia refrigeration unit, triggering fluctuations in the steam network of the ammonia synthesis plant as well as vibrations and displacement variations within the equipment.

(2) This results in significant deviations in the high-pressure system components—specifically, a low ammonia-to-carbon ratio and a high water-to-carbon ratio—leading to reduced conversion efficiency in the high-pressure system, a noticeable increase in steam consumption, heavier loads on downstream systems, and difficulty maintaining optimal operation under high-load conditions.

(3) Significant leakage from the mechanical seal, if not detected promptly, can lead to a low liquid level in the sealing water tank, causing the sealing water pump to fail to deliver adequate flow. This, in turn, may trigger a low-sealing-water-pressure interlock, ultimately resulting in the high-pressure ammonia pump shutting down unexpectedly.

(4) If the seal water pressure differential control valve is not adjusted promptly in manual mode, it may allow liquid ammonia to leak through the mechanical seal into the seal water system, contaminating the water in the seal water tank.

Regarding its coking industry and the corrosive nature of ammonia water, the operation procedures for ammonia water pumps must ensure mechanical sealing integrity. To achieve this, the sealing components need to meet the following requirements: tightness with minimal leakage; high safety and reliability, coupled with an extended service life; and a simple design that facilitates easy maintenance. DFP-Type Multi-Stage Corrosion-Resistant Centrifugal Pump Employing an advanced hydraulic model and crafted from corrosion-resistant stainless steel, this pump features a secure sealing design that eliminates axial movement during mechanical sealing. Unlike older multi-stage high-pressure ammonia pumps, where axial misalignment often led to poor contact between the dynamic and static sealing rings, causing mechanical seal failure, this innovative design ensures tight, leak-free operation—preventing even a single drop of water from escaping. As a result, it serves as an excellent next-generation replacement for multi-stage centrifugal ammonia pumps that traditionally relied on balance disc structures.

Previous:

Next:

Recommended Information

Related Products