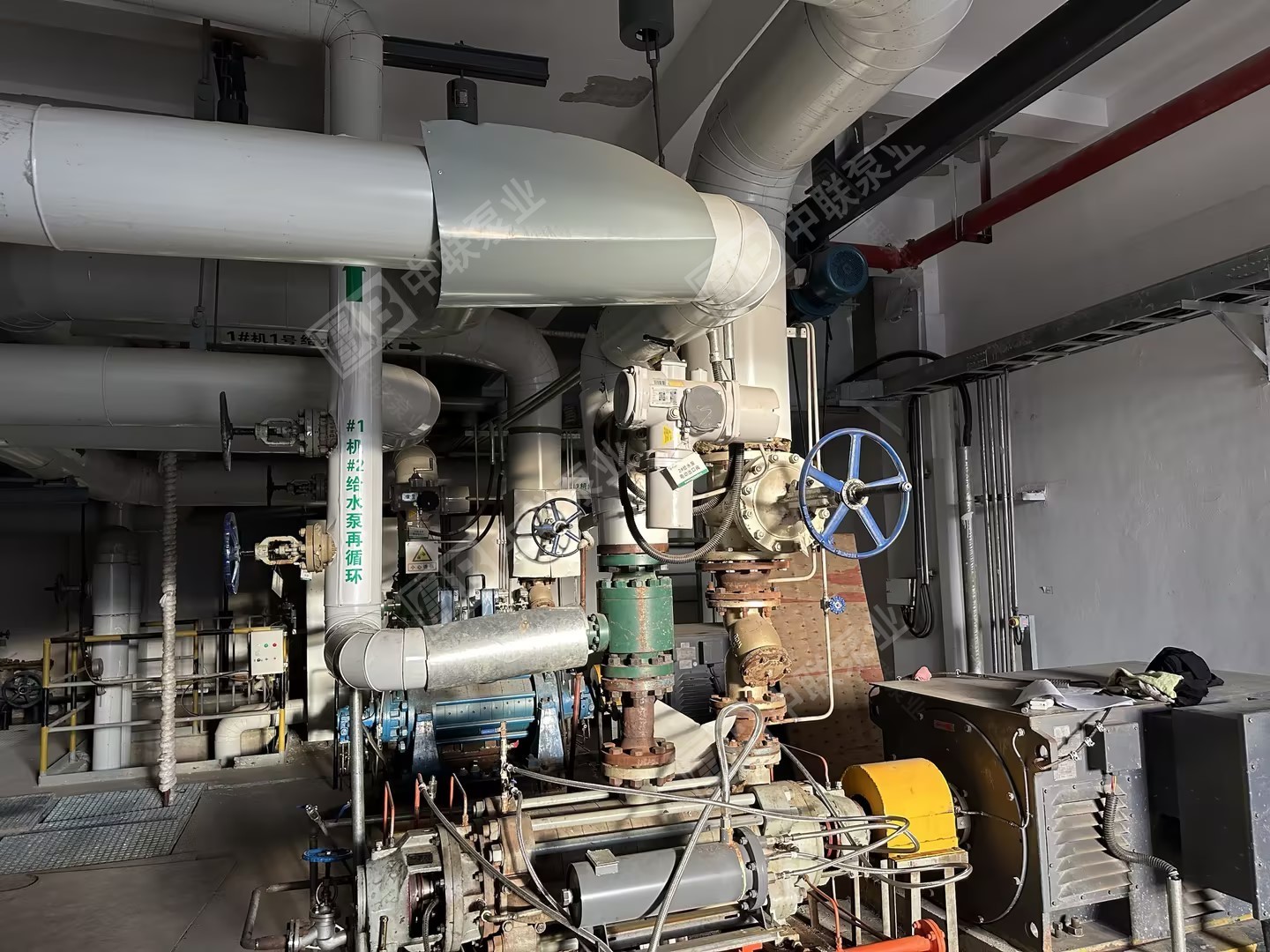

Horizontal multi-stage Centrifugal pump As the core equipment for fluid transportation, its sealing and lubrication components are crucial for ensuring the pump's performance and efficiency. In this article, a manufacturer of multistage centrifugal pumps Changsha Zhonglian Pump Industry This section will provide a detailed introduction to the role of seals in horizontal multistage centrifugal pumps and highlight the importance of proper lubrication, along with offering several optimization strategies to help you better understand and apply these technologies.

I. The Function and Principle of Sealing Components

The primary function of sealing components is to prevent fluid leakage within the pump, ensuring efficient and stable fluid flow inside the pump. Common sealing types include mechanical seals and packing seals.

1. Mechanical Seal:

Function: Mechanical seals are an efficient and reliable sealing method that prevents fluid leakage between the pump shaft and the housing by ensuring a tight fit between two flat surfaces or grooves.

Advantages: Low frictional power consumption, long service life, and easy maintenance. Mechanical seals are particularly well-suited for applications requiring high sealing precision, such as in industries like chemical processing and petroleum.

Application scenarios: Thanks to their outstanding sealing performance, mechanical seals are widely used in operating conditions with stringent leakage requirements—such as handling high-temperature, high-pressure, or corrosive media, as well as oils.

2. Gland Seal:

Function: Gland seals achieve a sealing effect by compressing填充 materials such as graphite, carbon fiber, and others. This type of seal boasts a simple structure yet offers excellent self-tightening properties.

Advantages: Suitable for fluids that are corrosive or contain solid particles. While packing seals aren’t as precise as mechanical seals, they perform exceptionally well in certain specific environments—particularly when handling fluids with impurities.

Application scenario: Packing seals are commonly used in situations where sealing requirements are relatively low but cost control is particularly sensitive, such as in the transportation of clean water.

II. Principles and Importance of Lubricated Components

The primary function of lubrication components is to reduce friction between the internal parts of a horizontal multistage centrifugal pump, thereby enhancing the pump's efficiency and extending its service life. Common lubrication components include bearing lubrication and gear lubrication.

1. Bearing lubrication:

Function: Reduce bearing friction by using lubricating oil or grease. As a critical component of multistage pumps, the lubrication condition of bearings directly affects the pump's overall performance and service life.

Advantages: Proper lubricants or greases can effectively reduce bearing wear, extend the pump's service life, and enhance operational reliability.

Optimization suggestion: Regularly inspect and replace the lubricant or grease, ensuring it remains clean and at an adequate level. Choose the appropriate lubrication product based on the specific operating conditions to achieve optimal performance.

2. Gear lubrication:

Function: Lubricating oil reduces friction between the gears, preventing excessive wear. In multi-stage pumps, the gears are responsible for transmitting power and flow—thus, their lubrication condition directly affects the pump's efficient operation.

Advantages: Proper gear lubrication not only reduces friction losses but also prevents the decline in power transmission efficiency caused by wear.

Optimization suggestion: Regularly monitor the lubrication condition of the gears, promptly replenish or replace the lubricant, choose high-quality oil, and adjust the lubrication frequency based on actual operating conditions.

In practical applications, it is necessary to select the appropriate sealing and lubrication methods based on factors such as the fluid properties and the pump's operating conditions. For instance, when handling high-temperature, high-pressure, or corrosive media, mechanical seals should be prioritized; meanwhile, for fluids containing solid particles, packed gland seals may be the better choice. Similarly, for different types of bearings and gears, the right lubrication product should be chosen according to their load requirements and environmental conditions.

Overall, the sealing and lubrication components of horizontal multistage centrifugal pumps are critical to ensuring their performance and efficiency. By making scientifically sound and well-considered selections and configurations, you can effectively enhance both the pump's operational efficiency and its service life. If you have any questions about horizontal multistage centrifugal pumps or require further assistance, please don't hesitate to contact us: 15616442288 (WeChat with the same number)—we look forward to providing you with professional support and services.

Recommended Information