In the chemical industry, Multistage chemical pumps are one of the indispensable pieces of equipment. They increase pressure through multiple working stages, enabling liquids to be transported to higher elevations or longer distances. Whether in the petroleum, chemical, or pharmaceutical industries, these pumps have a very wide range of applications. As multistage pumps and chemical pumps professional manufacturers, we at Changsha Zhonglian Pump Industry mainly produce two types of multistage chemical pumps: one is the balanced disc type DF horizontal multistage chemical pump, and the other is the DFP type self-balancing multistage chemical pump. The structures of these two pumps differ slightly; the former is an older multi-stage centrifugal pump structure, while the latter is a horizontal multistage centrifugal pump without a balancing device.

Please click the image to learn about the model parameters and product details of Changsha Zhonglian Pump Industry's 【DFP Type Self-Balancing Multistage Chemical Pump】.

1. Working Principle of Multistage Chemical Pumps

Speaking of the working principle, Multistage chemical pumps it uses multiple impellers to gradually increase the liquid pressure. Each impeller can be regarded as a small booster, and multiple impellers connected in series can achieve higher outlet pressure. This design not only improves efficiency but also enables large flow output within a smaller volume.

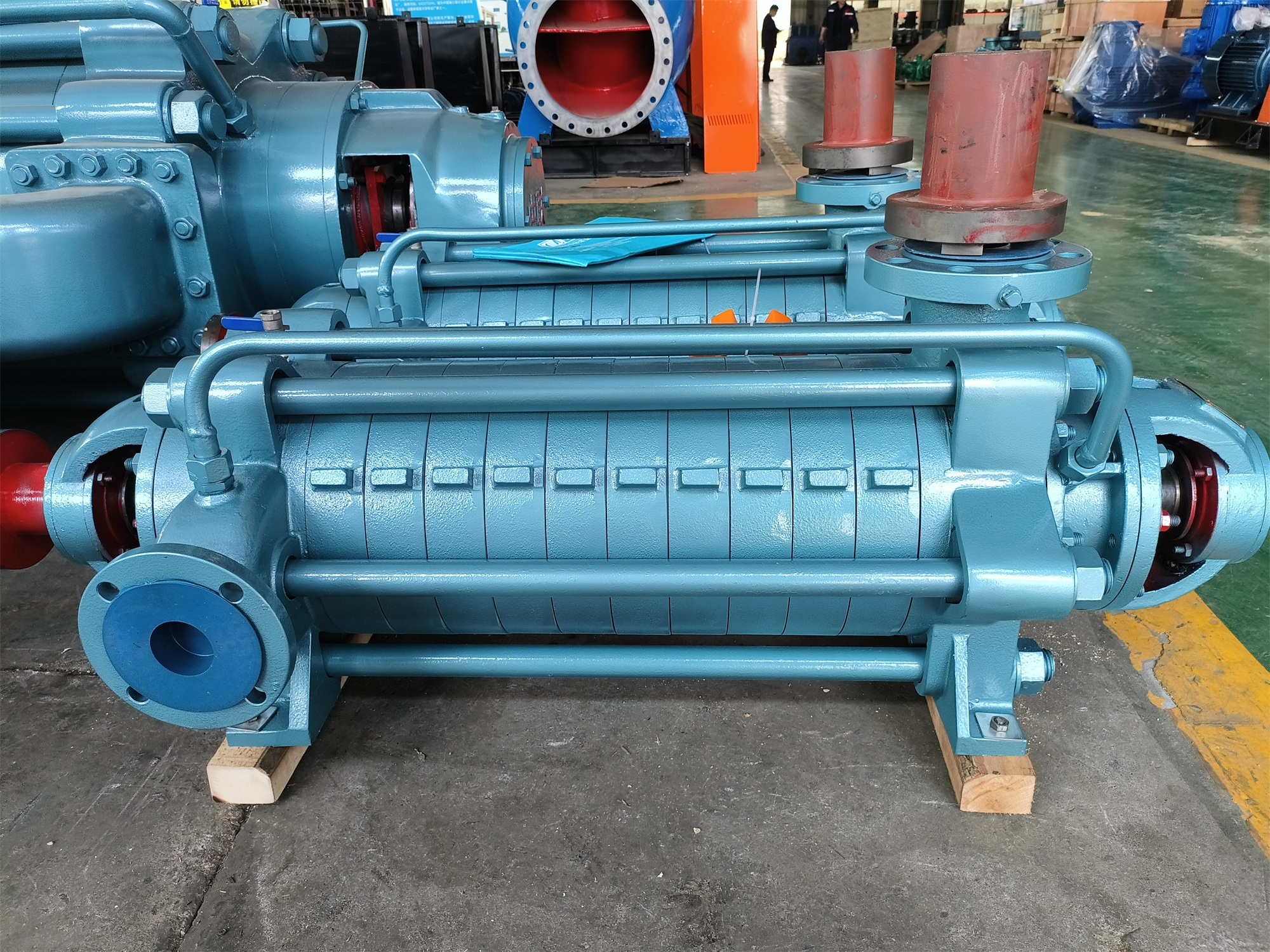

Please click the image to learn about the model parameters and product details of Changsha Zhonglian Pump Industry's 【DF Type Horizontal Multistage Chemical Pump】.

Common Question 1: Are multistage chemical pumps noisy?

Many users pay attention to noise issues when using Multistage chemical pumps them. In fact, the noise level of a pump mainly depends on its design and operating conditions. Generally, proper installation and regular maintenance can effectively reduce noise.

Common Question 2: How to maintain multistage chemical pumps?

Maintenance Multistage chemical pumps is key to ensuring their operation. Regularly checking the pump's seals, bearings, and impellers is necessary. Additionally, keeping the pump clean and preventing impurities from entering are also important maintenance points.

2. Common Faults of Multistage Chemical Pumps

Any equipment can experience faults, Multistage chemical pumps and pumps are no exception. Common faults include failure to start, insufficient flow, and leakage. When encountering these issues, first check the power supply, liquid level, and the pump's mechanical parts.

Troubleshooting Tips

If the pump does not start, first confirm whether the power supply is normal, then check the start switch and cable connections. If the flow is insufficient, it may be due to impeller wear or blockage. For leakage, check the condition of the seals and replace damaged parts promptly.

3. Application Fields of Multistage Chemical Pumps

Multistage chemical pumps Their applications are very extensive, mainly including:

- Transportation of petroleum and natural gas

- Transfer of chemical liquids

- Liquid transportation in the pharmaceutical industry

- Liquid handling in the food industry

Regardless of the industry, Multistage chemical pumps their performance and reliability are widely recognized.

In summary, Multistage chemical pumps as an important part of modern chemical equipment, their design and maintenance require professional knowledge. We hope this article helps you better understand and use this equipment, avoid common problems, and improve work efficiency!

Previous:

Recommended Information